At Sunbeam Elastomers Pvt. Ltd., we understand that quality is non-negotiable. To meet the highest standards of excellence, our state-of-the-art testing facility ensures that every product and material undergoes rigorous evaluation. From raw materials to final output, we leave no stone unturned in delivering dependable, high-performance solutions.

Why Testing is Critical in Manufacturing

Testing is the backbone of reliability and safety in industrial manufacturing. At Sunbeam Elastomers, we employ advanced testing techniques to verify the durability, precision, and quality of our products. This commitment ensures our clients receive solutions that meet global standards and withstand the toughest conditions.

Our Comprehensive Testing Capabilities

1. Raw Material Testing

- Ensures the consistency and purity of materials used in production.

- Identifies any impurities or inconsistencies to maintain product integrity.

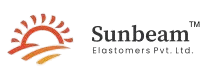

2. Physical Property Testing

- Tensile Strength Testing: Determines the ability of materials to withstand stress and stretching.

- Elongation Testing: Evaluates flexibility and durability under various conditions.

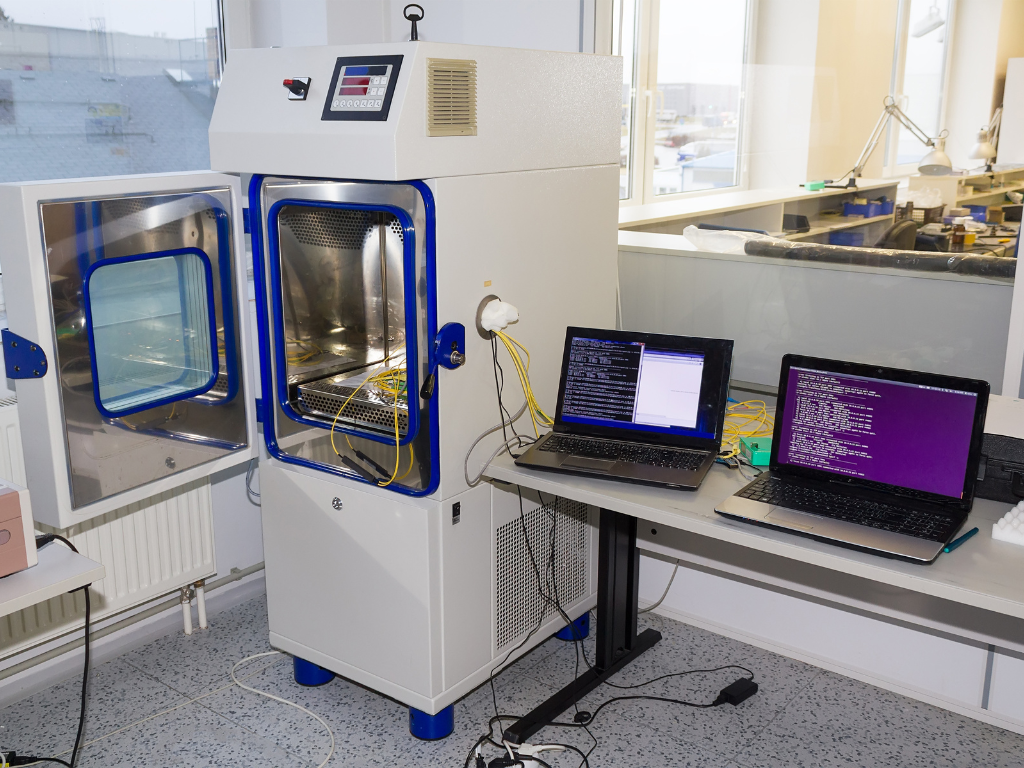

- Compression Set Testing: Assesses the material’s ability to return to its original shape after compression.

3. Hardness Testing

- Measures the hardness of rubber and elastomers to ensure they meet specific application requirements.

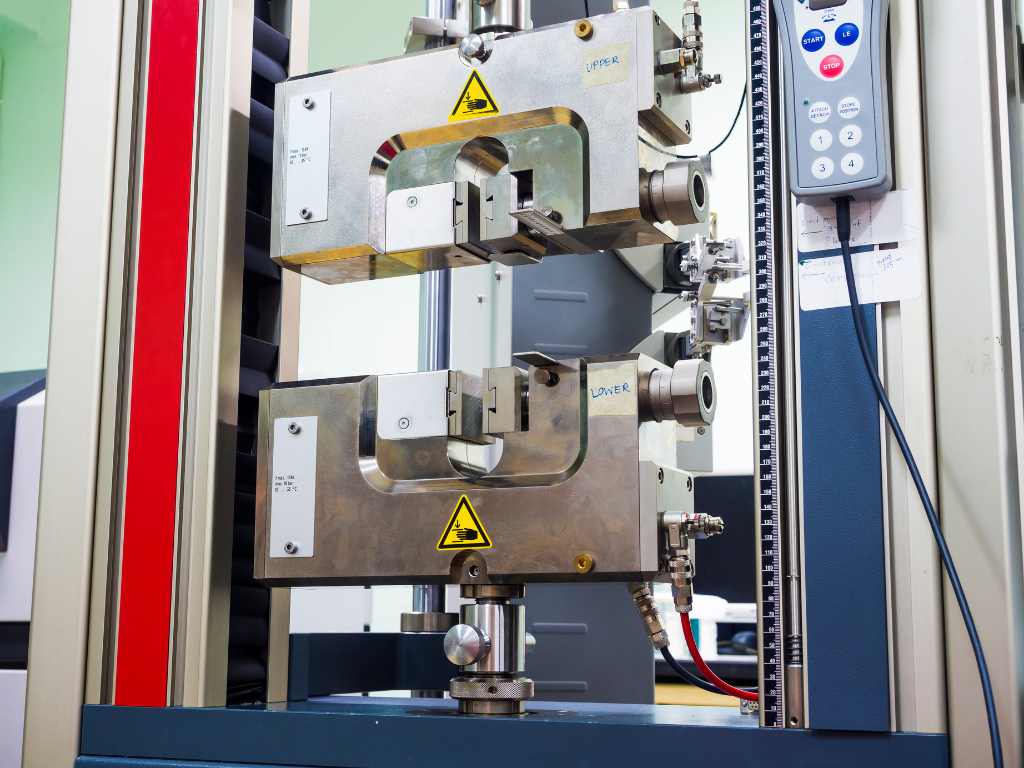

4. Aging and Weather Resistance Testing

- Simulates real-world conditions to assess the longevity and performance of materials under extreme temperatures, UV exposure, and other environmental factors.

5. Chemical Resistance Testing

- Tests material performance against oils, acids, alkalis, and other chemicals to ensure durability in harsh industrial environments.

6. Dimensional Accuracy Testing

- Ensures the final products meet precise specifications and tolerances for seamless industrial applications.

7. Adhesion Testing

- Verifies the bond strength of coatings, linings, and rubber-to-metal components to prevent failures in critical applications.

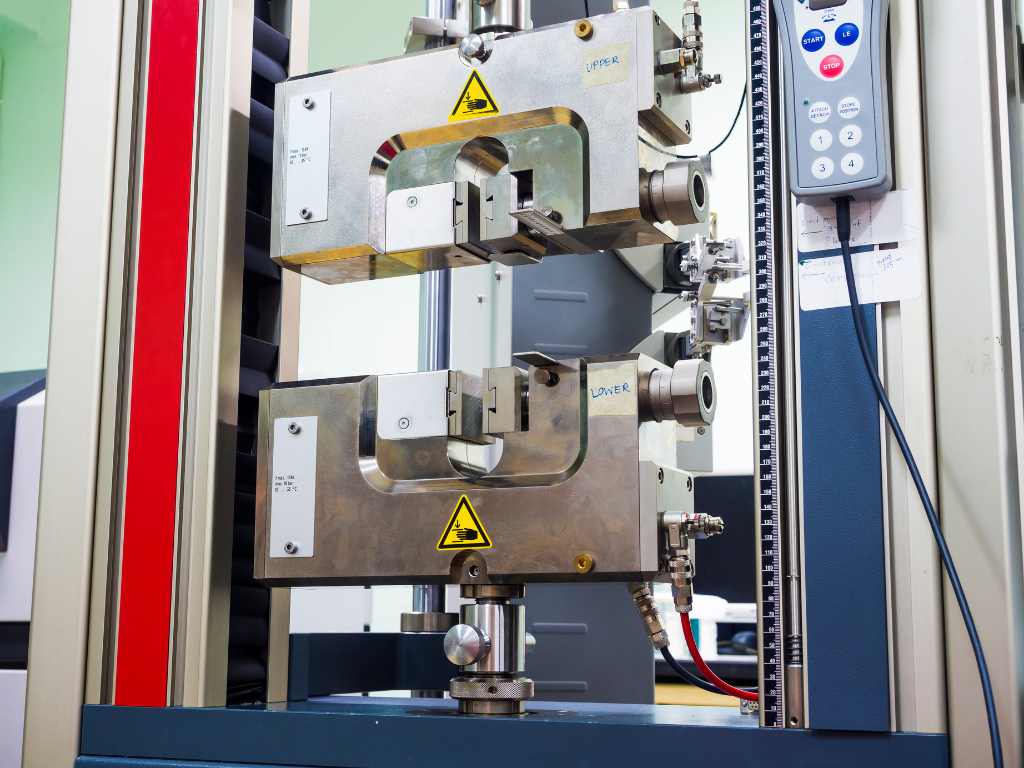

Advanced Equipment in Our Testing Facility

Tensile Testing Machine

Hardness Tester

Aging Chambers

Compression Testers

Chemical Exposure Chambers

Tensile Testing Machine

Hardness Tester

Aging Chambers

Compression Testers

Chemical Exposure Chambers

Our Commitment to Quality Assurance

At Sunbeam Elastomers, every product is thoroughly tested to ensure it exceeds client expectations. Our testing facility is staffed by experienced professionals who understand the nuances of material behavior and industrial demands. This attention to detail ensures our products are safe, reliable, and built to last.

Why Choose Sunbeam Elastomers' Testing Facility?

- Precision Testing: Advanced tools and techniques for accurate results.

- Comprehensive Analysis: From raw material to finished product, we test it all.

- Industry Compliance: Our testing processes align with global quality standards.

- Tailored Solutions: Testing customized to specific industry requirements.

Ensuring the Best for Your Industry

With Sunbeam Elastomers’ cutting-edge testing facility, you can trust that every product is designed and manufactured to perform under the most demanding conditions. We don’t just meet expectations—we set new benchmarks for quality and reliability.

Partner with Us for Dependable Solutions

Looking for industrial products that have been rigorously tested and certified? Look no further. At Sunbeam Elastomers, we combine innovation, expertise, and precision testing to deliver solutions you can trust.

Experience Excellence with Sunbeam Elastomers

Where quality meets reliability. Contact us today to learn more about our testing facility and how we ensure every product is a step above the rest.